UVL Drone: Making Warehouses Run Like Clockwork

Step into a giant warehouse, and it’s like walking into a maze from some old adventure flick—shelves piled high with boxes, pallets jammed in every nook, and workers hustling to count it all before the day’s done. It’s a whirlwind of clipboards, ladders, and squinting at tiny barcodes, hoping nothing gets missed. Manual inventory counts are a slog, plain and simple: they eat up time, invite mistakes, and sometimes put folks in dicey spots. Now, picture a zippy little drone buzzing through the aisles, scanning labels like it’s playing a high-stakes video game and nailing it. That’s the UVL Inventory Management Drone, sold through XBoom, and it’s shaking up how warehouses keep tabs on stock.

The Headache of Old-School Counts

Doing inventory by hand is like trying to count every jellybean in a jar while blindfolded. Teams trudge through aisles for days—sometimes weeks—hauling ladders, dodging forklifts, and scribbling numbers like there’s no tomorrow. In big warehouses, where thousands of items are stuffed across what feels like a small city, it’s a task that could drive anyone up the wall. Mistakes? Oh, they happen all the time: a barcode misread under flickering lights, a box tucked in the wrong spot, or a tired worker skipping a pallet by accident. Those slip-ups can mess up orders, pile up extra stock, or leave customers fuming. And the risks? Climbing wobbly ladders or weaving through heavy machinery is no joke—inventory day can feel like a safety obstacle course.

The UVL Inventory Management Drone, cooked up by UVL Robotics and available at XBoom, rolls in like a knight in shining armor. It’s not some flashy gizmo for show—it’s a real-deal fix for the chaos of stock counts. Here’s the rundown on what makes it such a big deal.

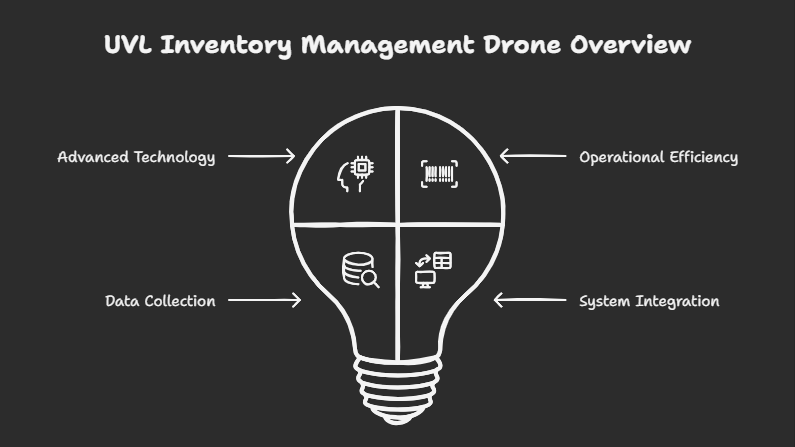

What’s the UVL Drone All About?

This ain’t the drone you’d fly for cool vacation shots or to drop off a burger. The UVL Inventory Management Drone is built for the rough-and-tumble world of warehouses, packed with brainy tech—think crisp cameras, sharp sensors, and AI that moves like it’s got the place memorized. It’s made to zip through narrow aisles, snag barcodes or QR codes in a split second, and keep going without a hiccup. Picture a super-smart bird that can read labels and never gets lost—that’s the UVL in action. It kicks off from a base station, cruises along shelves, and grabs data like it’s collecting treasure.

The info—pictures, scans, the whole shebang—gets sorted and turned into reports that slide right into warehouse systems. Whether it’s a tiny storage room or a sprawling logistics hub, this drone makes counting stock feel less like pulling teeth.

What’s got everyone jazzed about the UVL drone? It’s tackling the worst parts of inventory management with some serious swagger. Here’s the scoop.

Speed That’ll Blow Your Mind

In a warehouse, time’s tighter than a drum. Old-school counts can shut things down for days, especially in places packed with thousands of pallets. The UVL drone’s like a racecar, blasting through scans up to 50 times faster than humans. It can wrap up a full count before the lunch bell rings, letting warehouses check stock more often without hitting the brakes on daily work. It’s like swapping a clunky old bike for a rocket.

Accuracy That Doesn’t Miss

Mistakes in inventory are like stepping on a Lego—small but painful. A wrong scan can lead to too many boxes or not enough, ticking off customers and clogging up shelves. The UVL drone’s AI and fancy cameras nail every barcode, no matter how cramped or dark the aisle. Data gets crunched at a base station and pops out as clean reports that hook up with systems like SAP or Oracle. Managers get rock-solid numbers.

Safety That Keeps Things Chill

Warehouses can be tough spots. Workers climbing high shelves or dodging heavy equipment risk bumps, falls, or worse. The UVL drone takes on the sketchy stuff, flying to tricky spots and scanning without anyone playing stunt double. It’s a simple way to keep the crew safe and let them stick to tasks that don’t involve tightropes.

Plays Nice with Your Setup

Warehouses depend heavily on software, and the UVL drone fits perfectly in like it’s part of the family. Its data flows into systems with formats like XML or EDI, delivering the real-time data necessary updates without forcing anyone to rewrite the playbook. It’s a boost that doesn’t demand a tech makeover or the relentless how-to sessions.

Saves Dough, Helps the Earth

Efficiency’s about stretching every dollar and resource. The UVL drone slashes the hours spent on counts, letting workers tackle bigger stuff like filling orders or brainstorming. It also skips paper records, cutting waste and giving a nod to greener vibes. For businesses watching their wallet and the planet, it’s a two-for-one deal.

Real Stories, Real Wins

Big shots like PepsiCo have used UVL Robotics’ tech to manage warehouses with 25,000 pallets, cutting count times and keeping workers safer since 2019. Kimberly-Clark leaned on drones during the pandemic to track stock without putting folks at risk. Smaller warehouses are jumping in too—one slashed its inventory time in half.

How It Pulls It Off

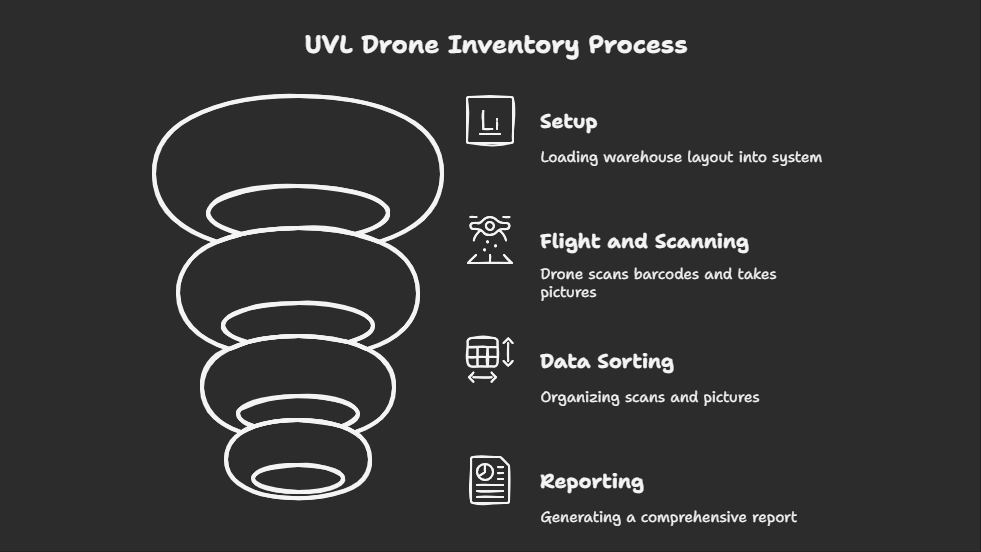

Here’s the quick and dirty on how the UVL drone works its charm:

- Setup: The warehouse’s layout gets loaded, mapping out every shelf and aisle.

- Flight and Scanning: The drone takes off, zipping through and grabbing barcodes with its cameras.

- Data Sorting: Scans and pictures go to a base station, where they’re organized and tied to the warehouse map.

- Reporting: A sharp report’s ready to plug into systems, no hassle.

The AI handles tight corners and weird setups, so even the messiest warehouses are a piece of cake.

Where Warehouses Are Going

The UVL Inventory Management Drone isn’t just a cool gadget—it’s a peek at the future. Warehouses are turning into slick, data-driven hubs, and this drone’s paving the way. It’s making counts faster, safer, and greener, raising the bar for logistics. For any business ready to ditch the old grind, the UVL drone, available through XBoom, is the ticket to a smoother, smarter setup.