Robots Revolutionizing Warehouses

With the rapid growth of logistics and e-commerce, warehouses must manage larger volumes with speed, accuracy, and safety. However, manual operations often fall short in meeting this rising demand. As a result, many businesses now turn to automation.

Industrial robots are transforming warehouse operations at their core. They optimize resources, reduce errors, and boost productivity. Moreover, they perform repetitive tasks without fatigue or delay. This shift enables faster turnaround and better scalability.

At XBOOM, we deliver cutting-edge robotic solutions designed for modern warehousing challenges. Our robots streamline workflows, increase operational control, and reduce dependency on manual labor. In doing so, we help businesses break traditional limits and grow efficiently.

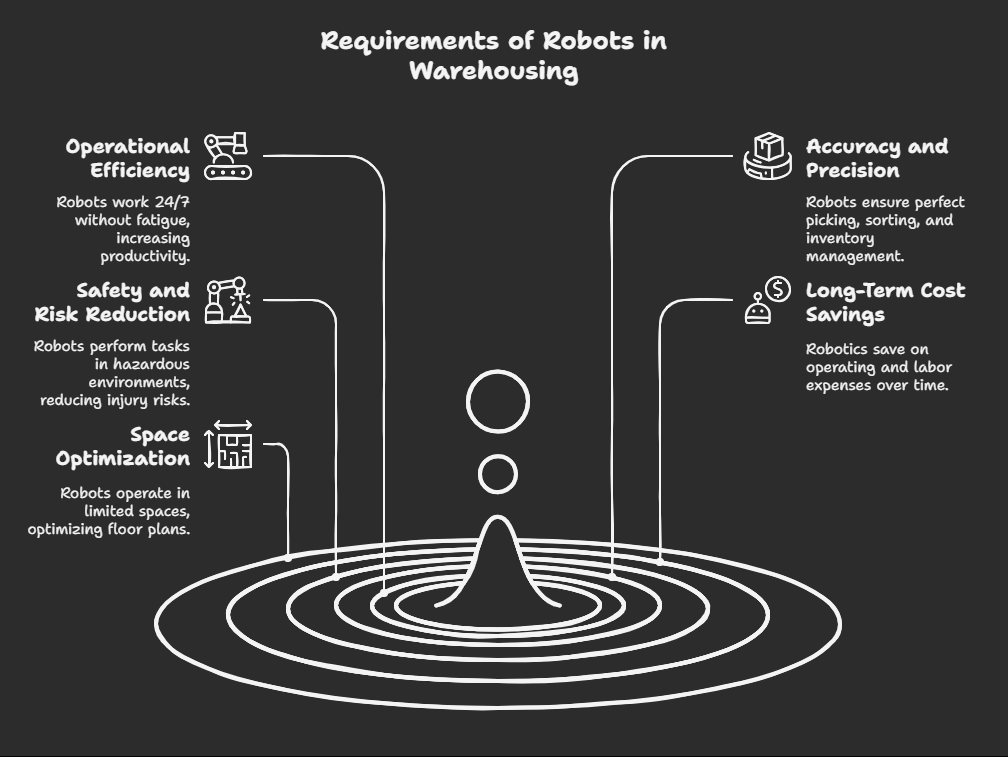

The Requirement for Robots in Today’s Warehousing

Warehouse operations involve repetitive and time-consuming tasks, often accompanied by the risk of fatigue and human error. Moreover, with limited manpower resources and rising operational costs, automation has become a necessity rather than just an option. In this context, robots offer significant advantages in various aspects.

Operational Efficiency: Robots work 24/7 without needing a day off, performing tasks efficiently without the risk of fatigue.

Accuracy and Precision: Furthermore, they ensure flawless performance in picking, sorting, and inventory management, guaranteeing consistent results.

Safety and Risk Reduction: Additionally, robots can handle tasks in hazardous or congested environments, significantly reducing the risk of injury to human workers.

Long-Term Cost Savings: While robotics may involve an initial investment, they lead to substantial savings in long-term operational and labor expenses.

Space Optimization: Moreover, space-saving and mobile robots are capable of operating in limited spaces, thereby optimizing floor plans and inventory locations effectively.

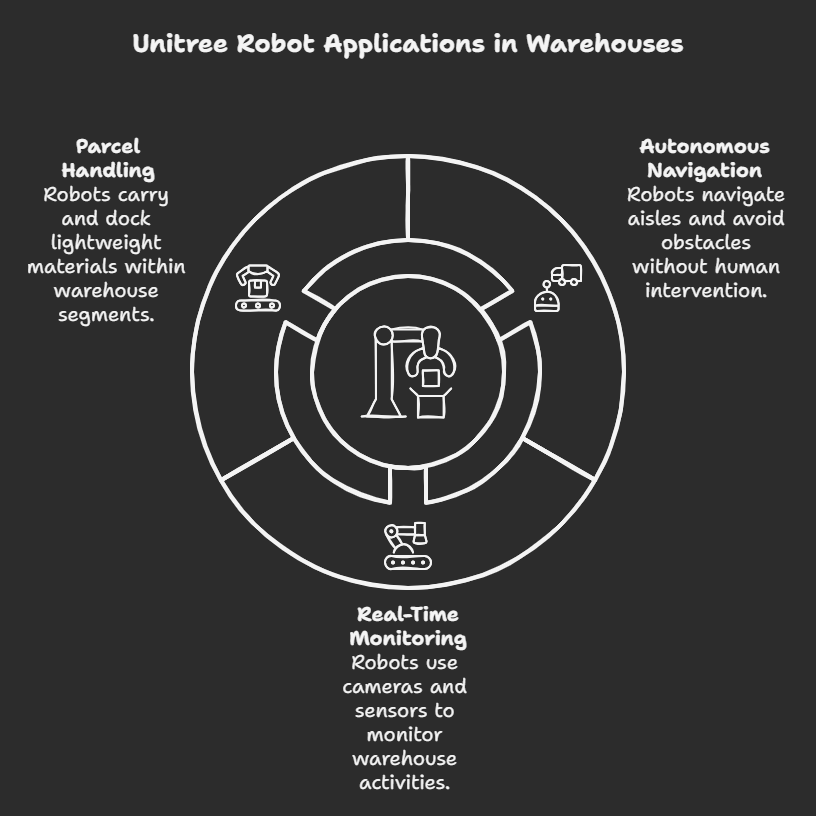

Unitree Go2 & Go2W – Dynamic Quadruped Robots for Dynamic Environments

Unitree’s four-legged autonomous robots are specifically designed to handle dynamic terrain and environments:

Autonomous Navigation: Powered by AI and LiDAR, Go2 robots navigate aisles, detect obstacles, and autonomously re-route in real time without the need for human intervention.

Real-Time Monitoring: Additionally, with integrated cameras and onboard sensors, the robots provide continuous, real-time monitoring, reducing reliance on traditional, static security systems.

Parcel and Inventory Handling: Furthermore, with payload and docking capabilities, these robots efficiently carry lightweight materials across various segments, minimizing the need for human labor.

Unitree Go2W (Waterproof Version): For environments that are semi-wet or outdoors, the Go2W effortlessly operates, ensuring reliable performance in various conditions.

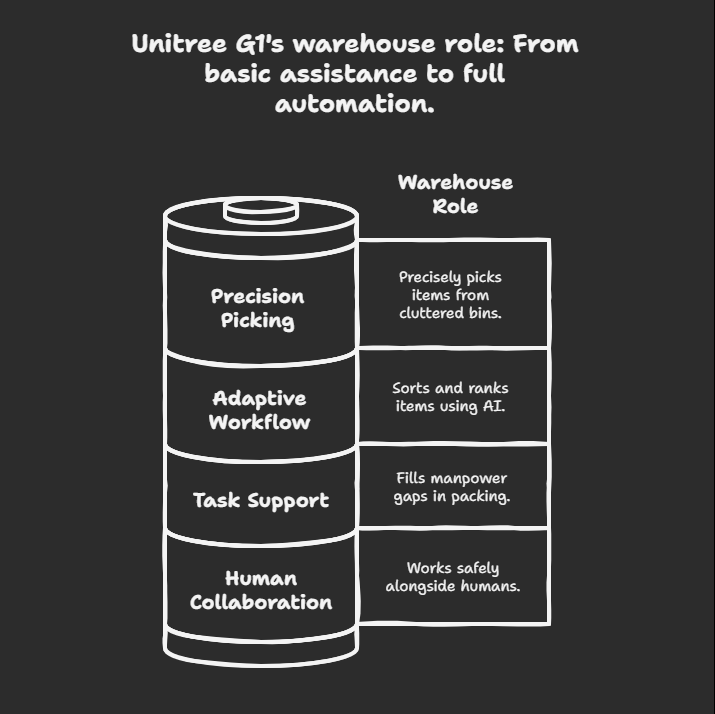

Unitree G1 – Humanoid Robot for Sophisticated and Efficient Warehouse Operations

Unitree G1 is designed for more complicated and human-centric warehouse processes:

Accurate Sorting and Picking: With 23 to 43 high-torque motors, G1 is capable of precision picking and setting down items from cluttered bins.

Intelligent Decision-Making: Artificial intelligence-based decision-making software enables it to sort, rank, and act on adapting workflows.

Packing and Maintenance Support: G1 can support packing or control units, closing capability gaps within manpower.

Team Support: It can interact safely with humans, contributing to output without substituting workers.

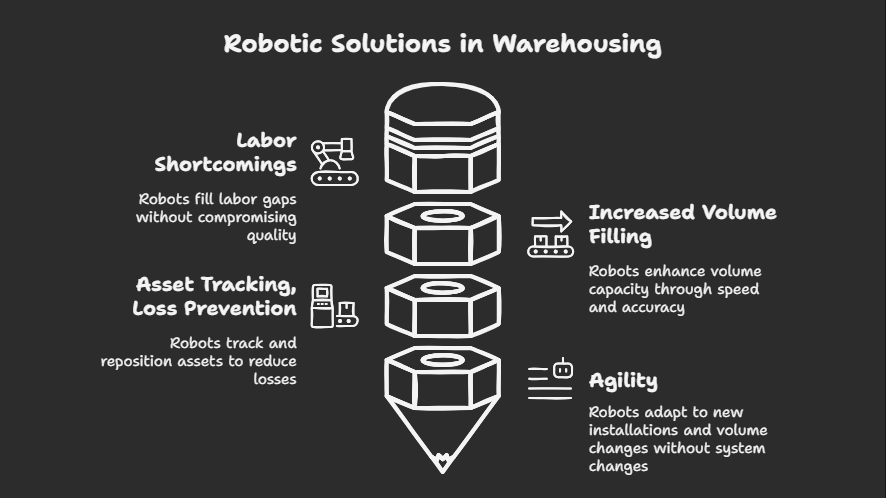

Warehouse Pains Being Reduced By Robotic Capabilities

Labor Shortcomings: Robots like the G1 and Go2 effectively address labor shortages without compromising quality.

Increased Volume Filling: Moreover, their accuracy and speed ensure the capability to handle optimum-end volumes with precision.

Asset Tracking, Loss Prevention: In addition, with advanced location tracking and real-time repositioning, robots minimize both inventory and product loss.

Agility: Furthermore, these robots seamlessly adapt to new installations or unplanned volume expansions, all without requiring system reconfiguration.

Conclusion: Invest with XBOOM’s High-Tech Robotics

Unitree Go2: Ideal for autonomous navigation, inventory tracking, and internal delivery.

Unitree Go2W: Suitable for warehouses with exposure to outdoor or semi-wet conditions.

Unitree G1: Suitable for applications that require high accuracy such as picking, sorting, and packing.

Trials need to be done at various Sites to check suitability from a Security usage point of view. Is it possible?